Die Wear-Resistant Stainless Steels

NIPPON KINZOKU Calls Attention to the L-DieL Finish

Kalin Ned — July 17, 2025NIPPON KINZOKU's L-DieL Finish stainless steel represents a significant innovation in metalworking materials, one that offers a sustainable solution to the persistent challenge of die wear in press operations. This specialized surface treatment modifies the naturally occurring chromium oxide layer on stainless steel, which is typically responsible for corrosion resistance but problematic for tool longevity. The innovation addresses this through a proprietary process that softens the passive film while maintaining the base material's structural integrity and anti-corrosion properties.

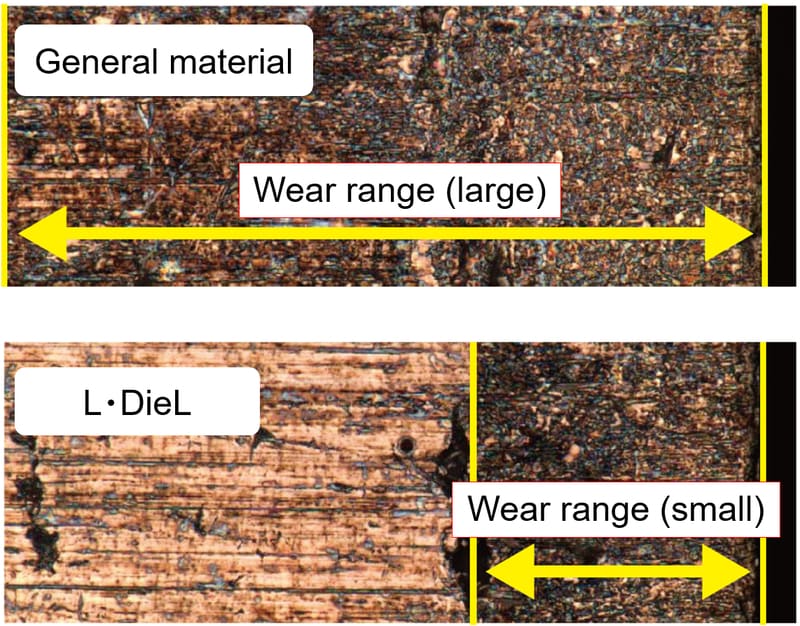

NIPPON KINZOKU's L-DieL Finish technology demonstrates particular effectiveness with common stainless steel grades like SUS304 and SUS430 across thicknesses from 0.08mm to 0.50mm. By substantially reducing abrasive wear on forming dies, the product promises to extend tool life significantly, as evidenced by comparative wear testing showing markedly improved performance versus conventional materials under demanding conditions.

The company has strategically positioned L-DieL Finish within its environmental initiatives, certifying it as an 'Eco-Product' that aligns with both its 2050 carbon neutrality goals and the 'Near Net Performance' philosophy of minimizing processing waste.