Sustainable Product Loop Partnerships

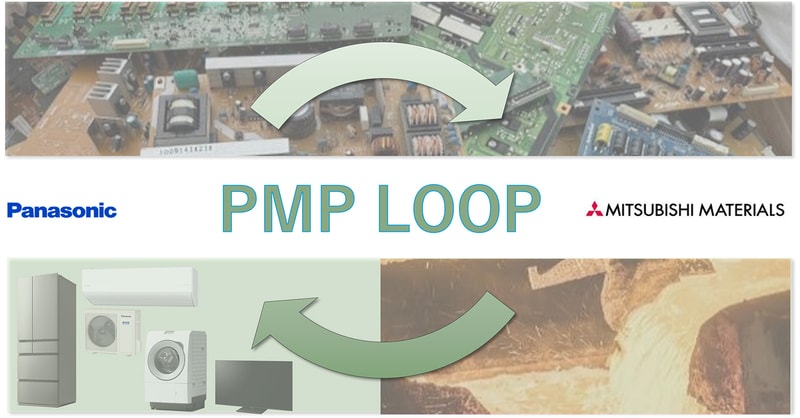

Mitsubishi Materials and Panasonic Partnered on a PMP Loop

Colin Smith — July 24, 2025Mitsubishi Materials Corporation and Panasonic Corporation’s Lifestyle Appliances and Solutions Company have jointly established a Product-Material-Product (PMP) loop to recover gold, silver and copper from waste printed circuit boards of discarded home appliances. Under this scheme, Panasonic ET Solutions Co., Ltd. outsources the processing of collected circuit boards to partner firms, which refine the material by removing iron and aluminum before transferring it to Mitsubishi Materials for smelting. Extracted metals are returned to Panasonic for reuse in manufacturing processes. Since its launch in 2011, the loop has reclaimed 1.1 tons of gold, 33 tons of silver and 8 100 tons of copper from urban mine resources.

The PMP loop also contributes to carbon-emissions reduction by substituting recycled metals for virgin ores. Recovering 8 100 tons of copper in lieu of conventional ore smelting has resulted in an estimated 33 000 tons of CO₂ savings. The initiative aligns with Japan’s Growth-Oriented, Resource-Autonomous Circular Economy Strategy and the Ministry of the Environment’s Fifth Fundamental Plan for Establishing a Sound Material-Cycle Society, which targets a doubling of processed metal recycling raw materials by fiscal year 2031. Both companies plan to expand end-to-end resource recycling management, explore additional target materials and collaborate with new partners to further the circular economy and reduce environmental impact.